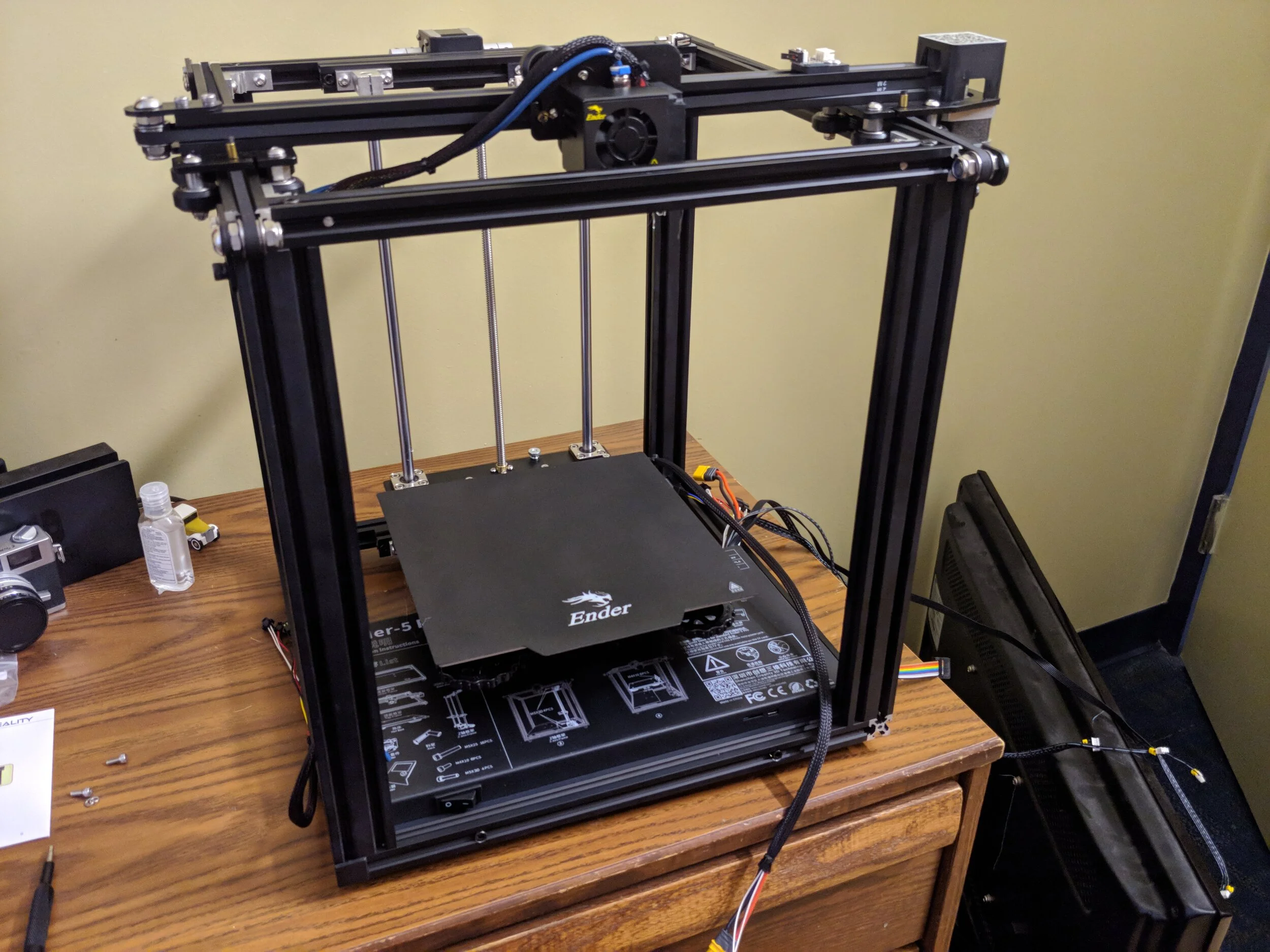

Customized 3D Printer

I recently got a 3d printer, specifically an Ender 5 Pro, and quickly made plans to modify it. This thread will document the modification journey of my 3D printer. Note: This is an ongoing project.

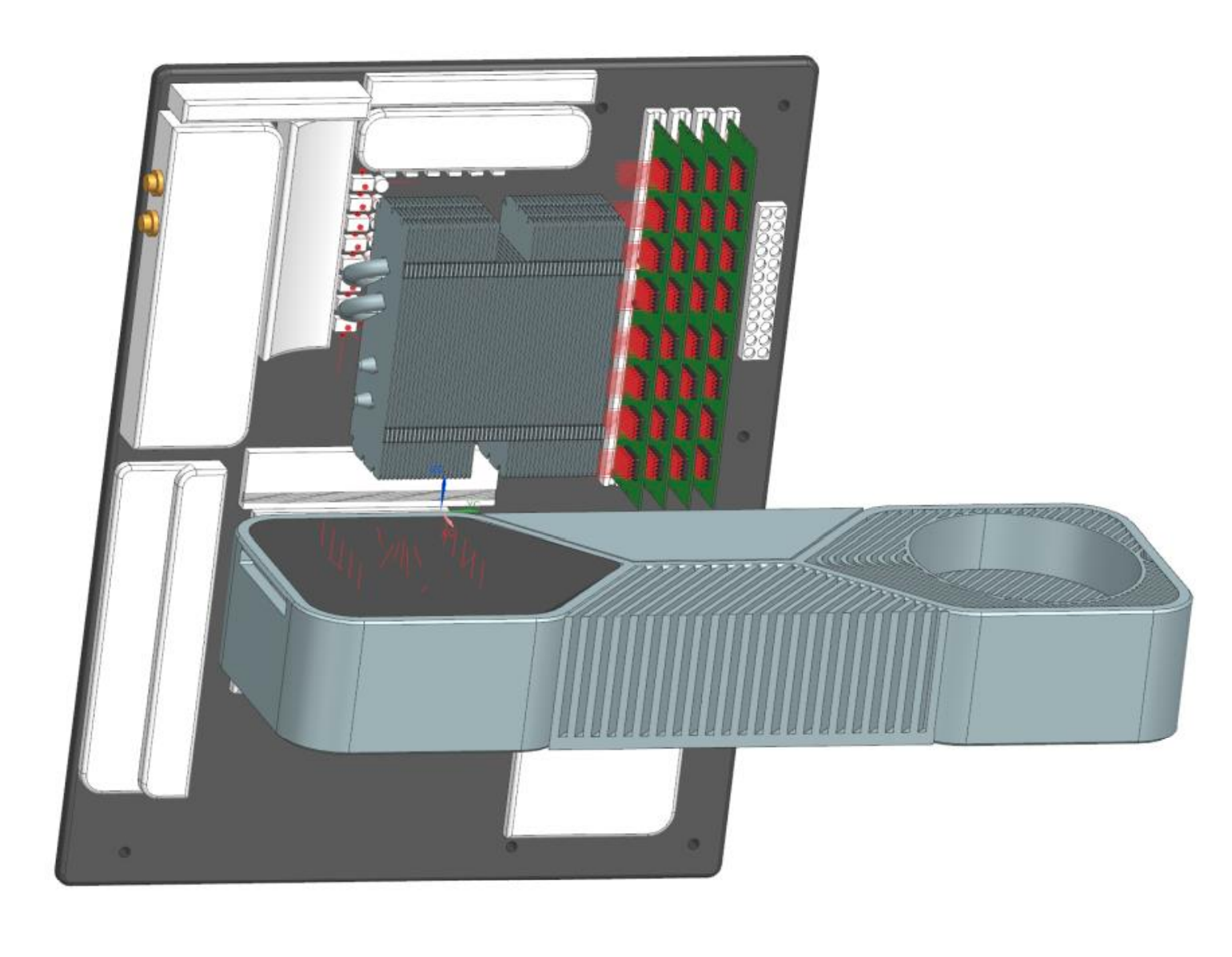

PC Case Thermal Simulation

This project involved modeling and simulating a desktop computer with the novel (at the time) pass-through heatsink found on Nvidia’s 3000 series GPUs, and assessing the accuracy of our models by comparing the results with real-world data. My responsibilities in this group project were modeling the CPU heatsink and simulating the assembly in Siemens NX.

Headphone Mount

I was frustrated with keeping my headphones in my desk drawer so I decided to quickly design and print a mount I could adhere to the wall. Since designing such a mount is fairly easy, I took this opportunity to learn generative design practices in Fusion 360.

Advanced Surface Modeling: VW Beetle

For a project in my advanced CAE course, I modeled a near-accurate VW Beetle. This is probably the most complex surface-based modeling I have attempted, and I am pretty happy with how most of it came out.

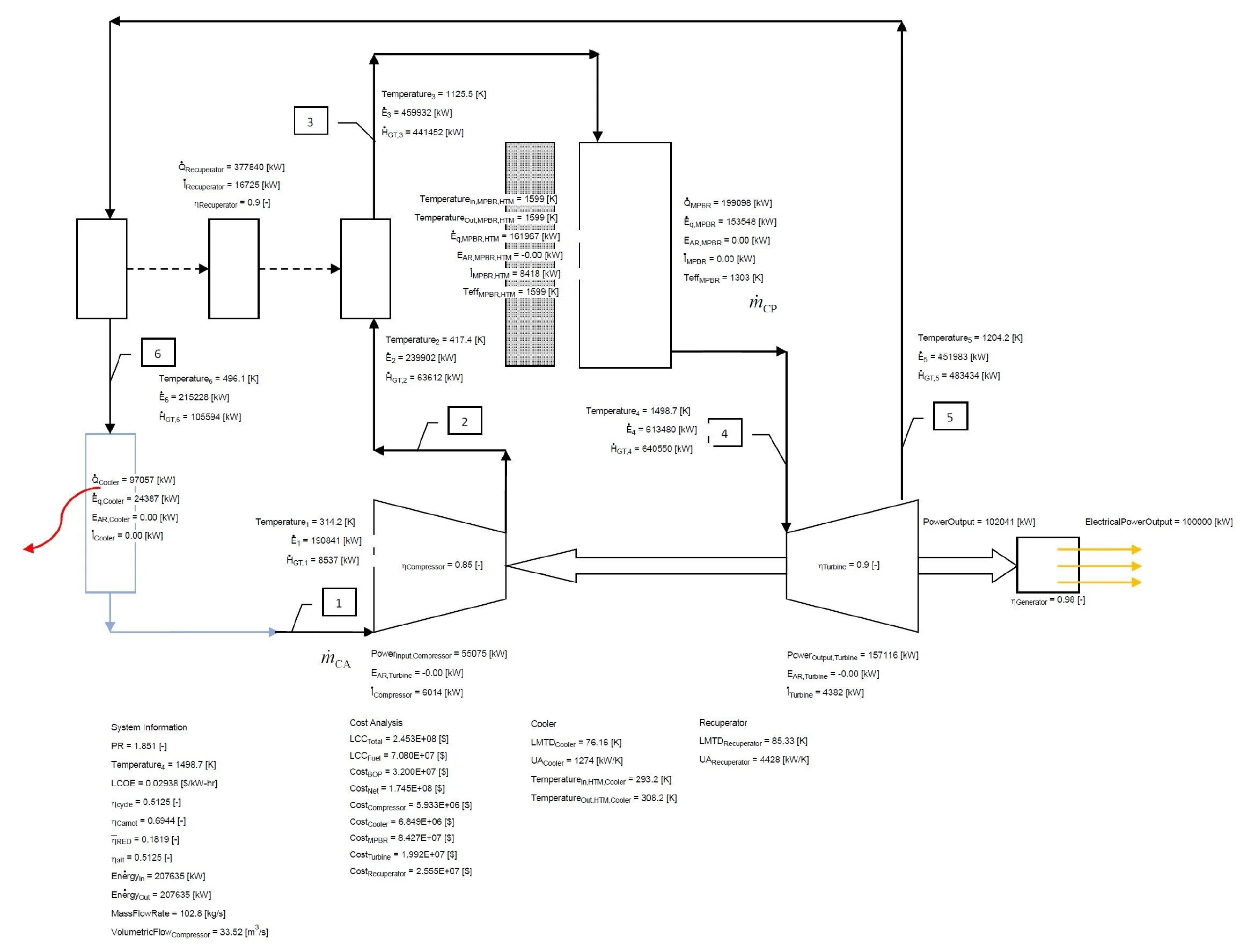

Modular Pebble Bed Reactor Energy System

For my final project in Energy Systems, I modeled a modular pebble bed nuclear reactor with a closed gas turbine system. The gas turbine was mathematically modeled in EES to determine the pressure ratio for the minimum life cycle cost.

Oregon Topographic Map

My roommate wanted to make a topographic map around his family’s cabin as a gift for his parents. I helped him plan out the project and taught him how to use the CNC in the Invention Studio so that he could make his gift idea.

Heat Transfer Project

For a heat transfer project, I modeled convection and radiation of a heat sink fin under thermal load. The temperature and heat flux distributions were determined using an ANSYS steady-state thermal simulation.

“Hard Copy” Resume

To stand out at an Apple recruiting event, I engraved my resume onto a sandblasted piece of aluminum. While a simple project, I definitely made an impression at the recruiting event. The recruiters thought I had purchased it online and were amazed when I told them I had not.

Replacement Pipe Fitting

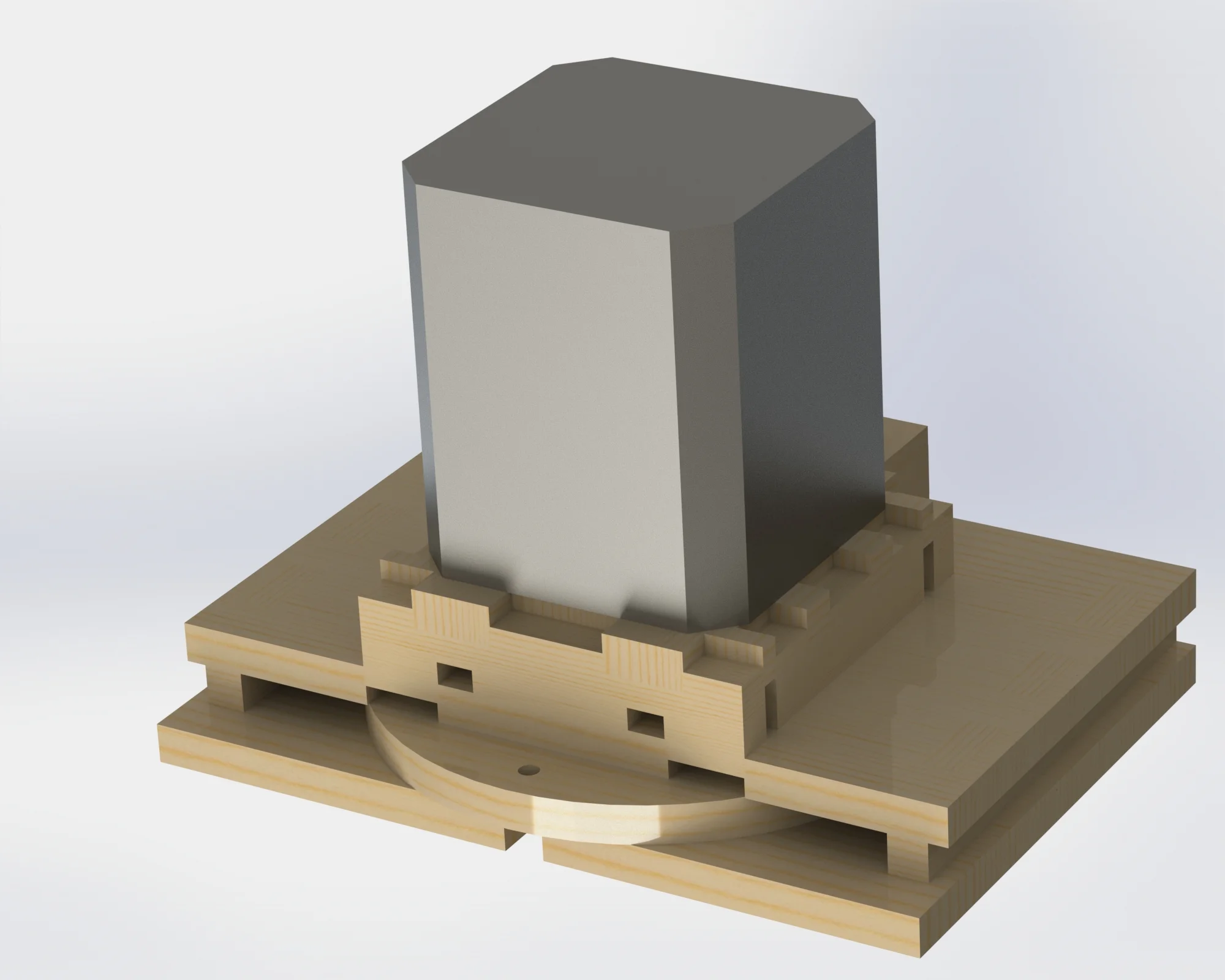

My dad had cracked a pipe fitting for his gardening hose. I ended up reverse engineering the broken pipe fitting and 3d printed it.

MSE 3021: Thermal Properties of Materials

This paper written for MSE 3021 - Materials Laboratory 1 investigated the investigate the thermal properties of various materials. Tests performed includes Differential Scanning Calorimetry (DSC), Thermogravimetric Analysis (TGA), Dynamic Mechanical Analysis (DMA), Fourier Transform Infra-Red (FTIR), and Thermal Transmittance tests.

MSE 3021: Electrical Properties of Materials

This paper written for MSE 3021 - Materials Laboratory 1 investigated the relationship between electrical properties and differences in atomic or chemical arrangement. The electrical proterties of metals and semiconductors are investigated by potentiostatic and galvanostatic tests. Additional experimentation involving circuit analysis and spectrophotometry was performed.

MSE 3021: Mechanical Properties of Materials

This paper written for MSE 3021 - Materials Laboratory 1 investigated the mechanical properties of polymers and metals utilizing industry-standard testing equipment. Tensile tests and Charpy impact tests were performed on metal samples, and stress relaxation and creep tests were performed on polymer samples. Experimental results were compared to the micro-structure characteristics of each material.

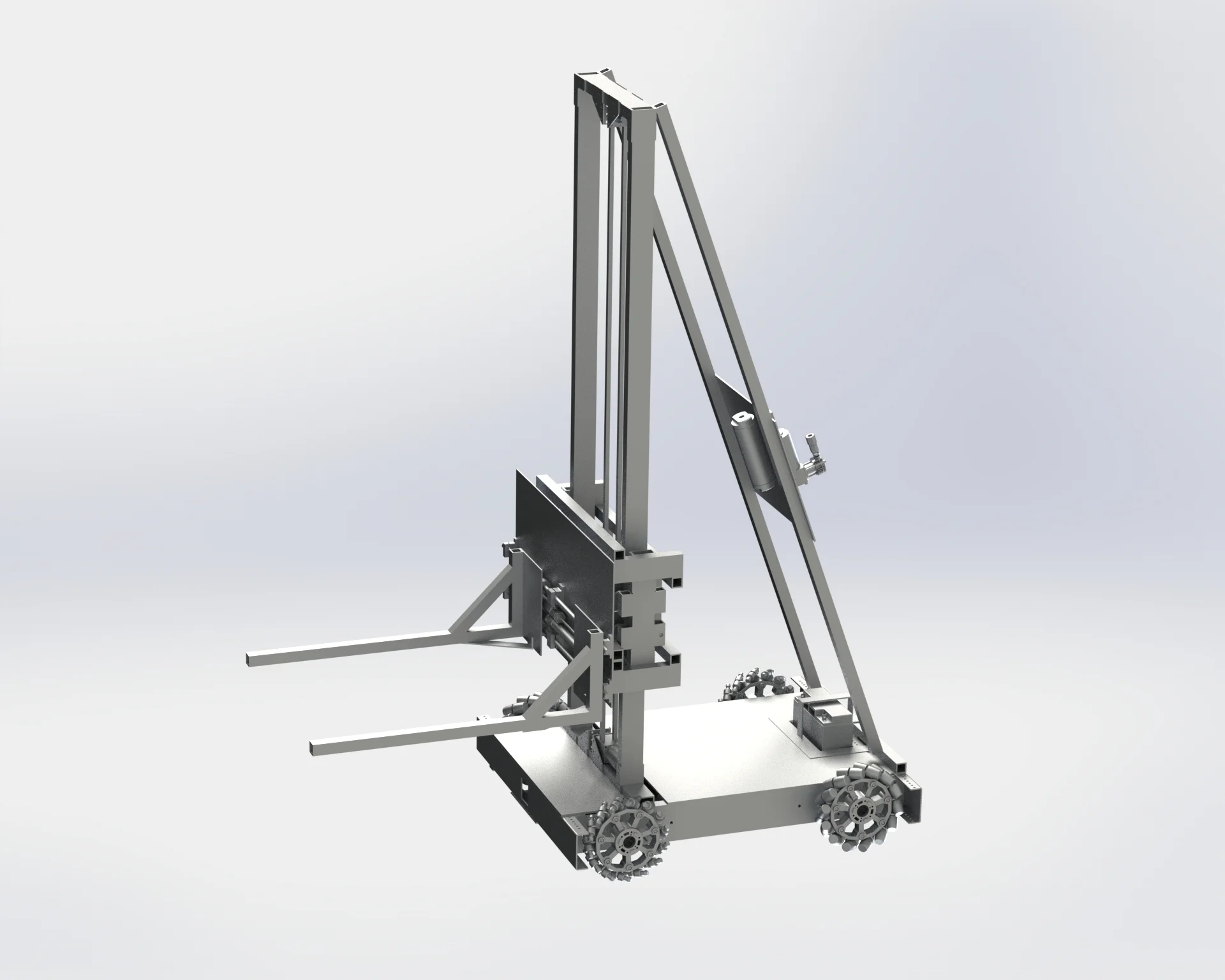

ME 2110: Competition Robot

This robot was designed for the ME 2110 - Creative Decisions and Design Robotics Competition. This course puts 60 teams of 4 students against each other to prototype, design, and build a working robot within a single semester. I was the lead designer for my team developing the main subsystems for each game mechanic. My team place 9th overall in the competition and 4th overall in the design review.

Automatic Fish Feeder

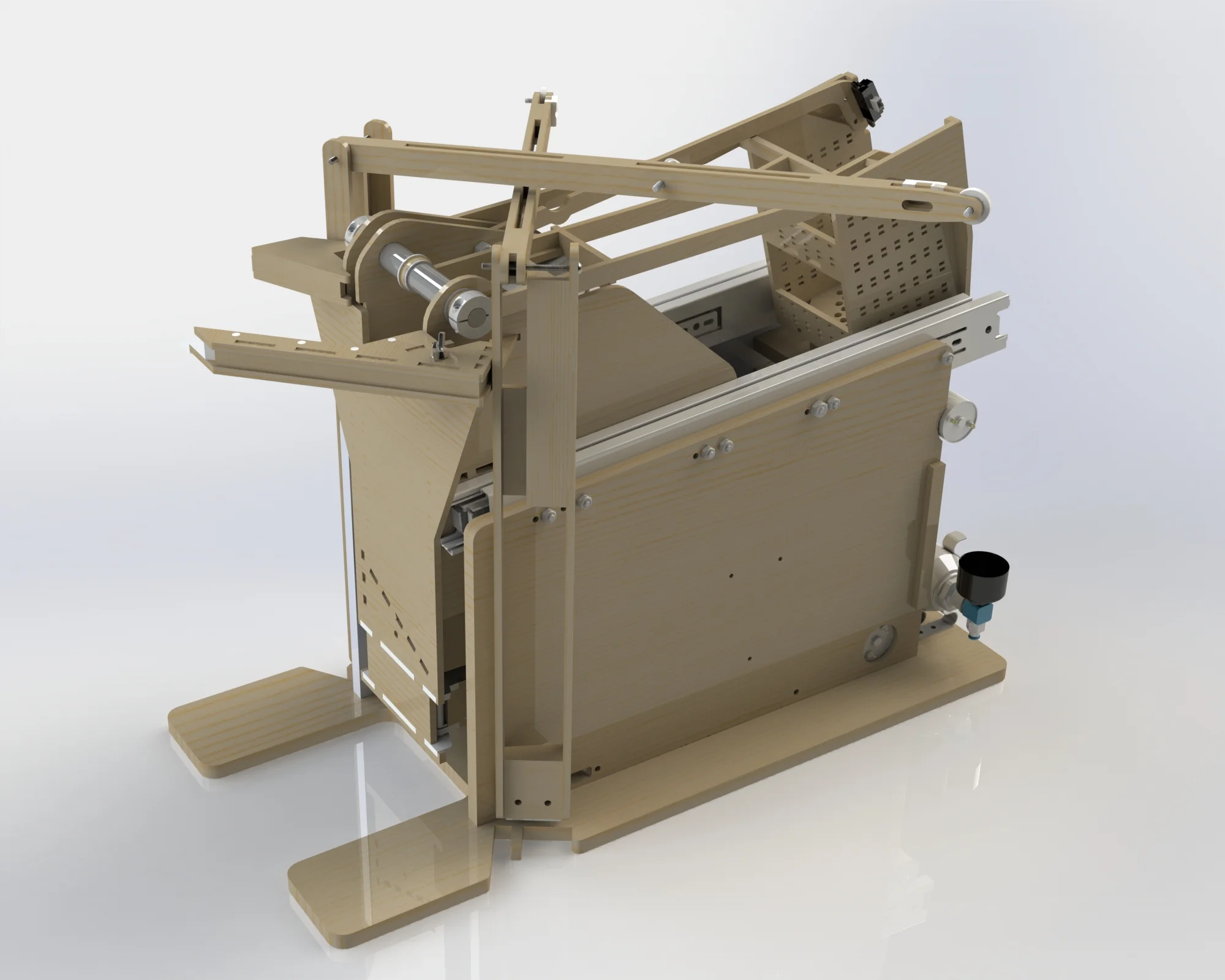

During my sophomore year at Georgia Tech, I purchased a betta fish to keep me company. I was worried about feeding it over breaks so I designed and built an automatic fish feeder using a stepper motor, laser-cut wood, and an Arduino.

ME 2016: Boundary Value Numerical Methods

This project for ME 2016 - Computing Techniques utilizes boundary value numerical methods to analyze the torsional vibrations of a wind turbine shaft. The maximum twist of a wind turbine shaft is calculated based on the shaft’s material properties.

ME 2016: Initial Value Numerical Methods

This paper written for ME 2016 - Computing Techniques investigates the benefits and drawbacks of various numerical methods. ODE45, Euler’s Method, and Heun’s Method are used to evaluate vibration in wind turbines.

ME 2016: Root Finding and Numerical Integration

This project for ME 2016 - Computing Techniques investigates root finding and numerical integration techniques. The power output of tidal turbines was calculated based on water velocity data.

ME 2016: Analysis of Line Fitting Techniques

This paper written for ME 2016 - Computing Techniques investigates the ability of various line fitting techniques in the context of wind turbines. Power output and vibration damping expressions are applied to asses the accuracy of the experimentally derived models.

1970s Road Bike Restoration

As an avid mountain biker, I typically don’t ride road bikes often. When I saw this old, beat-up Concord Pro-II road bike from 1974 on Craigslist, I knew I needed to buy and restore it. After rebuilding the bike from the ground up, I used it as my “daily driver” throughout my time at Georgia Tech.

FRC Robotics 2016

This robot was designed and built for the 2016 FIRST Robotics Competition: Stronghold. For this competition, I developed a unique drive-train system to handle the rough field terrain. A custom water-jetted frame and specialty treads enabled the robot to cross rough terrain bidirectionally.

FRC Robotics 2015

This robot was designed and built for the 2015 FIRST Robotics Competition: Recycle Rush. After gaining CAD experience during the 2014 competition, I put my CAD skills to the test as the only designer for Pisgah Robotics for the 2015 season.

FRC Robotics 2014

This robot was designed and built for the 2014 FIRST Robotics Competition: Arial Assist. Working with the team’s mentors, I designed many of the functional mechanisms of my team’s robot. Interestingly, this was the first year CAD was used to design Pisgah Robotics’ Robot.