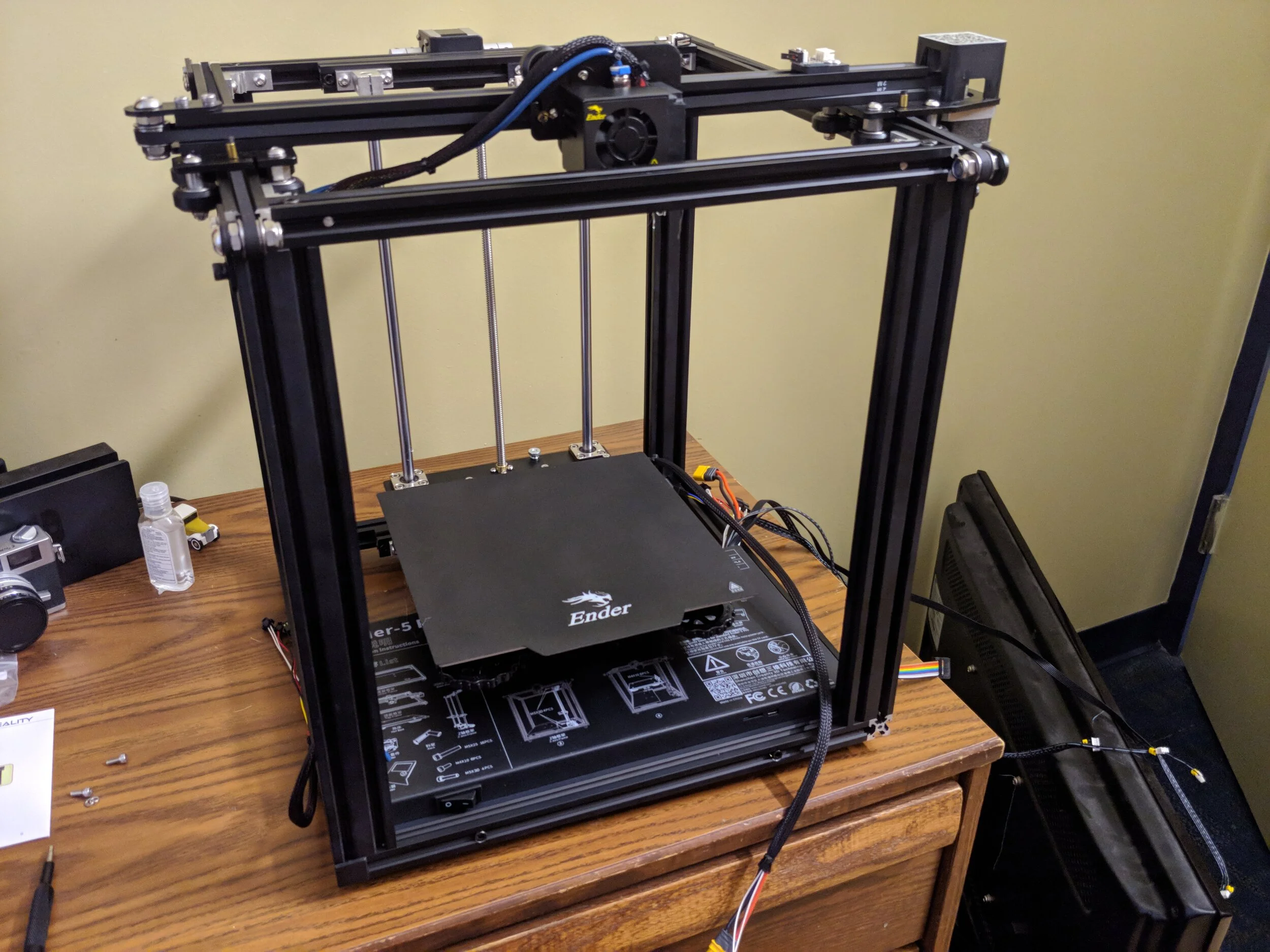

Customized 3D Printer

About

I recently got a 3d printer, specifically an Ender 5 Pro, and quickly made plans to make extensive modifications to it. This thread will document the journey of my 3D printer in all its glory. Above is a picture in its unmodified state, which it remained for about 10 minutes until I dismantled it for modifications.

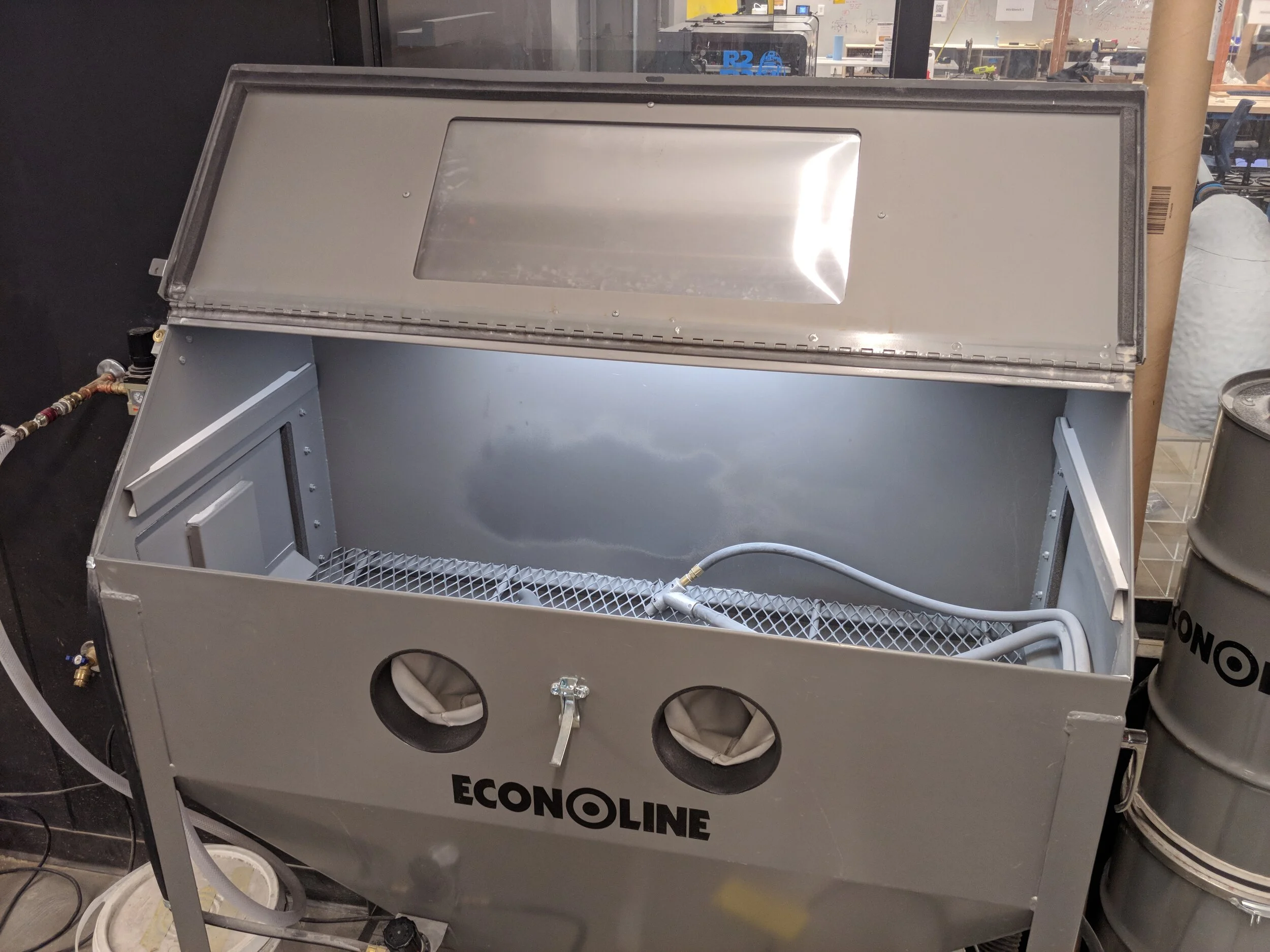

My first modification involved sandblasting all of the aluminum extrusions used in the frame of the 3d printer. This was purely an aesthetic choice since, while harder than raw aluminum, scratches in black anodized aluminum are easily visible. While there were some concerns of friction issues developing on sliding components, they were determined to be minor after some testing.

My first print was a model of a kiwi bird I found on Thingiverse. While its not a good print for benchmarking, it was a quick and easy print I could use to tell if there were minor printing issues.

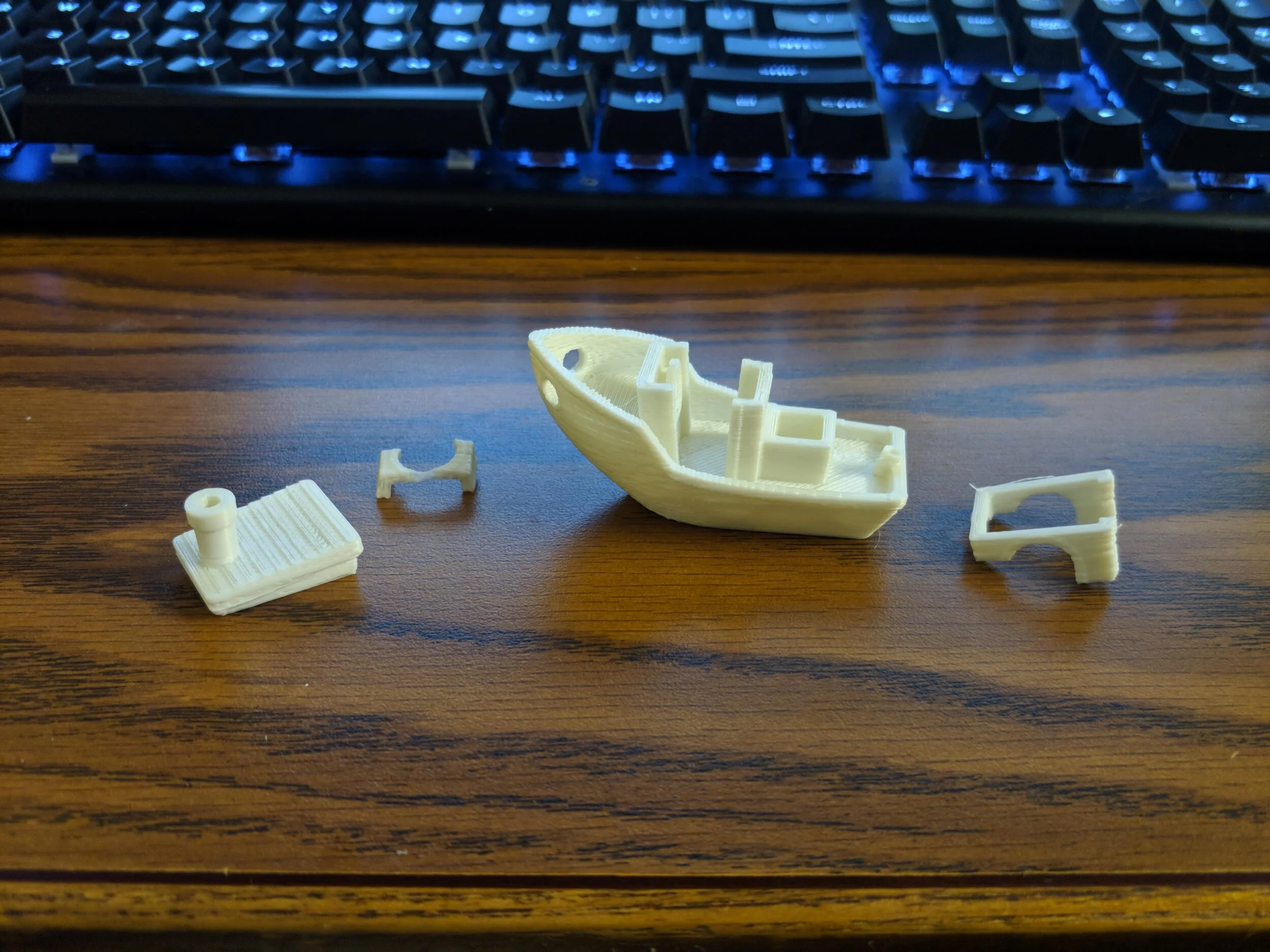

To get a better idea of print issues, I printed “Benchy,” a standard 3d print benchmarking model. Here you can see delamination issues caused by under extrusion. This was fixed by marking a specific length of filament, telling the printer to extrude that same length, and measuring the difference between the marked length and extruded length. That difference is used to calculate a feed compensation constant for correcting differences in expected and actual extrusion lengths.

My next steps involve adding TL Smoothers, side panels, an updated extruder, bed supports, and auto homing bed.

This is an ongoing project. Please return later for updates.